- Time:2023/9/19 Posted:ZY Metal Manufacturing(HK) Limited

Can the magnesium alloy die-casting process undergo electroplating surface treatment?

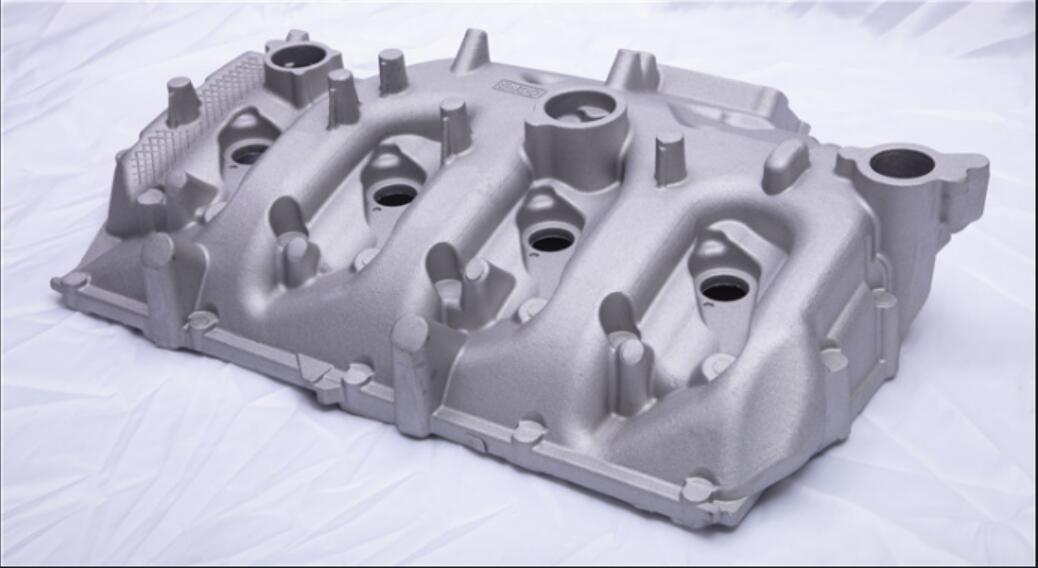

Magnesium alloy die-casting is a processing method that uses pressure to inject molten magnesium alloy into a mold for forming. This processing technology has the advantages of fast forming speed, high production efficiency, and high product accuracy. Electroplating surface treatment involves attaching a layer of metal to the surface of the product to improve its hardness, corrosion resistance, and aesthetics. So the question arises, can the magnesium alloy die-casting process undergo electroplating surface treatment?

Can the magnesium alloy die-casting process undergo electroplating surface treatment?

Surface Characteristics of Magnesium Alloy Die Casting

Magnesium alloy die-casting products have a smooth and clean surface, excellent mechanical properties and corrosion resistance, but their surface will turn black due to the corrosion of aluminum and zinc, which will affect the product's aesthetics. Therefore, surface treatment is necessary.

Electroplated surface treatment

Electroplating technology refers to the process of attaching a thin layer of metal or alloy to the surface of a metal or other conductive material using electrolysis or chemical methods. Its advantages are high hardness, corrosion resistance, strong aesthetic and decorative properties of the copper and chromium layers.

Magnesium alloy die-casting and electroplating surface treatment

According to the research results, magnesium alloy products can be adhered to by electroplating, but the surface treatment of magnesium alloy requires special treatment to provide a sufficient surface pigment controller to enhance the adhesion and coating ability of the inorganic protective layer of electroplating. This special treatment includes the introduction of active ingredients on the surface and fine surface chemical oxidation treatment.

Summarize

Magnesium alloy die-casting process can undergo electroplating surface treatment, but special treatment is required to ensure excellent performance of the adhesion layer. This can significantly improve the corrosion resistance, aesthetics, and wear resistance of the product.

A professional factory company in the die-casting industry for over a decade

Zhongyan Metal Manufacturing (Hong Kong) Co., Ltd.

Dongguan Meijing Electromechanical Technology Co., Ltd.

Mobile phone: 15322436212

Contact person: Miss Zhou

Email: zhouxiangqian@126.comWebsite: www.mjzymetal. com

Address: Building 2, No. 7 Huamei Road, West Tailong, Shatian Town, Dongguan City